Savage Industries located in American Fork, Utah began using DS-600i on their Cummins diesel engines and saw two primary benefits: cost savings and engine maintenance.

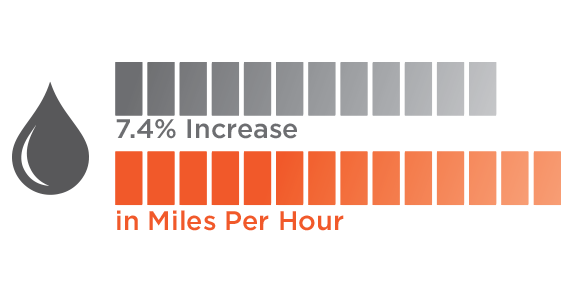

Savage concluded that over the first 10,000 miles driven, the average mpg of vehicles burning treated fuel was 2.29% better than that of vehicles burning untreated fuel. To their surprise the second 10,000 miles driven they experienced a 4.49% MPG increase, and the third 10,000 miles driven they experienced even better results with a 7.48% increase in MPG.

In addition to cost savings, when Savage performed routine maintenance they noticed a lack of carbon build up in the combustion chamber. Savage explained, “At this point, [We] can conclude with 90% confidence that the rate at which soot, silicon, chrome, and copper build up in the oil of vehicles burning treated fuel is significantly less than the rate of substance build up in the oil of vehicles which burned untreated fuel.”

Savage Industries used treated fuel in their Cummins engines for three years. When they had to do some maintenance on one of the engines they were shocked at what they found. “We recently had to perform a major maintenance procedure on one of our units powered by a Cummins engine. To our surprise we found no hard carbon buildup after 580,000 miles of use. Normally we have to chisel or use power equipment to remove the buildup. In this case we were able to wipe the combustion chamber clean with a shop cloth.” – Van Sawyer, Savage Industries